.: rear crossmember |

|

|

|

|

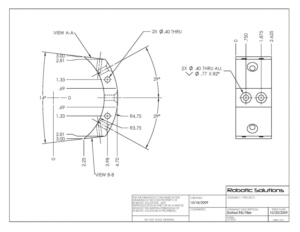

I again resorted to developing the

bracketing using a CAD model |

|

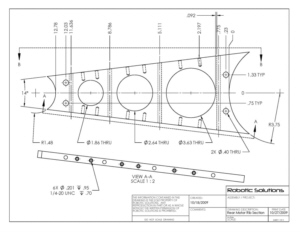

This is the main rib. I

initially had long through holes in

order to hold the entire assembly in

tension, but after analyzing the

stresses I determined they were not

necessary. (Robotic Solutions is a

sister company). |

|

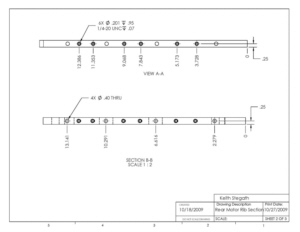

Hole locations needed to bolt

the rib to the horizontal members. |

|

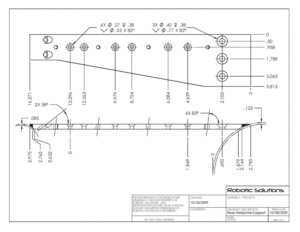

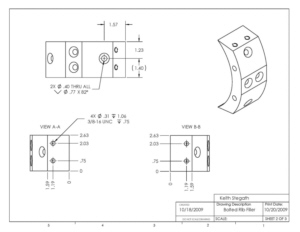

There are

three different horizontal members - two

mirror pieces, and one needed for

clearance at the driver's foot well. |

|

I did away with

the curvature as it didn't lock the

components together. Instead I notched

the "bellhousing" so that the weight of

the motor would tend to lock everything

together tighter - that's why I did away

with the through holes in the horizontal

members. |

|

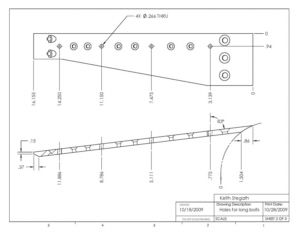

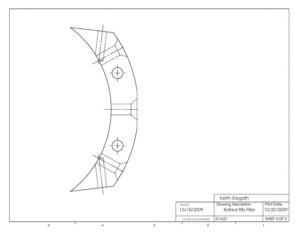

This is the main

filler member - sort of a keystone. |

|

Another drawing

of the "keystone". |

|

|

|

|

|

|

|

|

|

|

|

|